Pressurized Canister Containers

Our lineup of pressurized containers that are clean, functional, and safe, and are used for transporting products, such as high-purity semiconductor and medical materials. High-purity chemicals can be transported in a clean condition without exposure to the outside air.

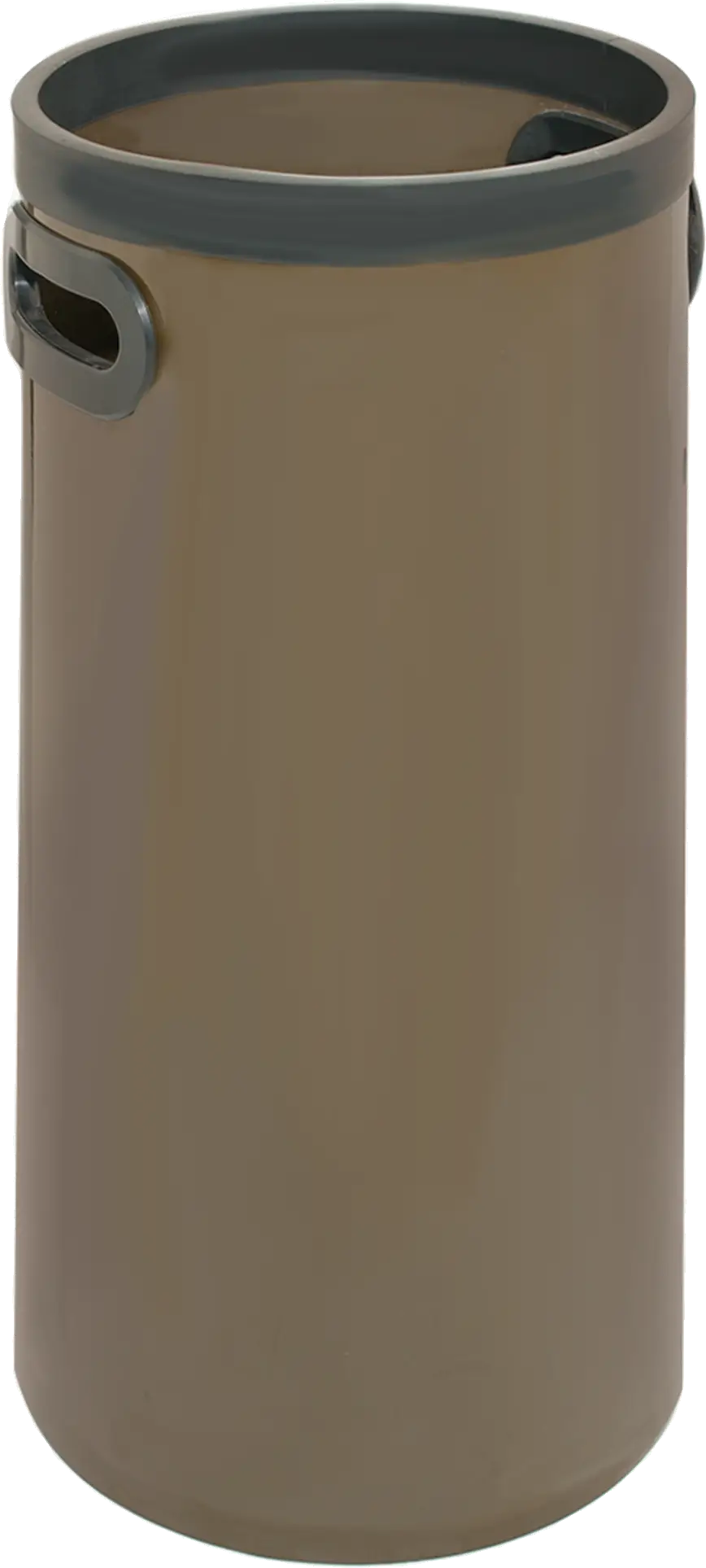

Small-scale containers

(composite and single)

This is a sub-20 L pressurized container for high-purity chemicals with excellent handling properties.

SUS Pressurized Canister Containers

This container is mainly used for organic solvents, flammable chemicals, and precursor materials, among others for semiconductor, liquid crystal, medical, and LiB-related applications.

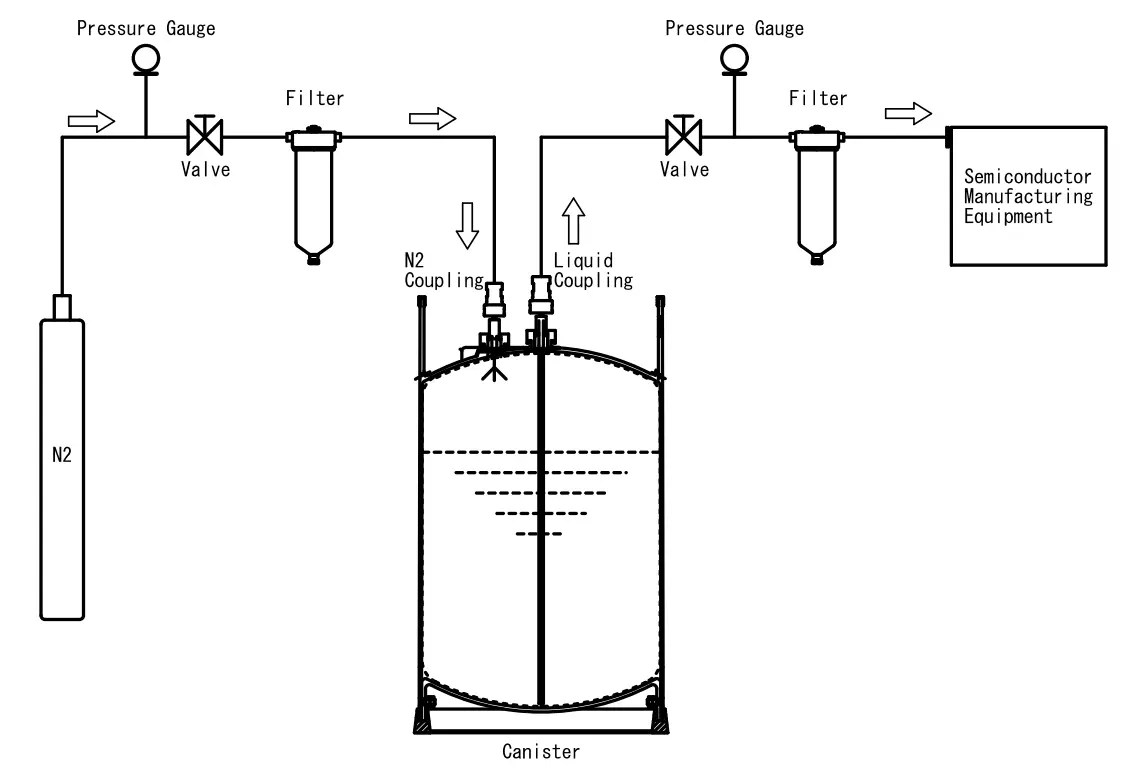

The method of pressurization enables chemicals to maintain their cleanliness while being supplied to production lines.

The inner surface is electropolished (EP) and cleaned with ultrapure water to provide a high quality product.

| Volume | 18L |

| Material | SUS304・SUS316・SUS316L |

| Inner surface treatment | Acid pickling/electro-polishing |

| Height | 609mm |

| Drum diameter | 230mm |

- The pressurized method allows the liquid to be in a clean condition when taken out.

- Electropolishing and acid cleaning are available in accordance with the quality of the chemicals.

- Enables ultrapure water rinsing or chemical rinsing to be performed before delivery.

- Can also be used for precursor materials through the use of a valve.

- Different capacities are available based on your request.

- UN-certified products that can be transported by sea are also available.

- Can be repeatedly used and is sustainable as a link container

- Uses

Electrolytes, High-purity solvents (IPA, PGMEA, etc.), Various cleaning agents, Fluorinated solvents, Precursor materials (TEOS, etc.)

Composite Pressure Canister Containers

A composite container combining a highly acid corrosion-resistant FRP or antistatic stainless steel exterior with a PE/PFA inner canister.

While maintaining the cleanliness of the chemicals using the pressurized method, it enables high-purity chemicals highly corrosive to stainless steel and chemicals of strict metal order to be supplied to production lines.

Wetted materials can be proposed based on the chemical quality requirements.

【Examples of combinations】

SUS/PFA: Combines a sturdy exterior and HDPE inner casing for long life and has a proven track record when used for a wide range of chemicals.

SUS Exterior

| Volume | 15L | 20L |

| Exterior | SUS | SUS |

| inner casing | PFA | PFA |

| Height | 500mm | 600mm |

| Drum diameter | 270mm | 270mm |

FRP/PFA: Rust-proof combination of FRP exterior and HDPE inner tube. Proven track record in the field of strongly acidic chemicals.

FRP Exterior

| Volume | 15L | 20L |

| Exterior | FRP | FRP |

| inner casing | PFA | PFA |

| Height | 540mm | 604mm |

| Drum diameter | 306mm | 306mm |

PE/PE: Used as SLB containers for many chemicals. 18L size, lightweight exterior, and boasts excellent handling performance.

PE Exterior

| Volume | 15L | 18L |

| Exterior | PE | PE |

| inner casing | PE | PE |

| Height | 520mm | 590mm |

| Drum diameter | 291mm | 291mm |

- Uses

High-purity acid cleaning agents (hydrochloric acid, sulfuric acid, hydrofluoric acid, acetic acid, mixed acid, etc.), High-purity hydrogen peroxide water, Developing solution (TMAH, etc.), Resist stripping solution - The pressurized method allows the liquid to be taken out in a clean condition.

- Wetted materials can be selected and proposed based on the chemical quality.

- Enables washing with ultrapure water or chemicals before delivery.

- As it can be combined with a degassing function, it can also be used for hydrogen peroxide and the like.

- Different capacities are available based on your request.

- UN-certified products that can be transported by sea are also available.

- Can be repeatedly used and is sustainable as a link container. The inner container is also replaceable.

Medium-sized containers

(composite, single, and lining)

This is a 100–200 L pressurized container for high-purity chemicals.

SUS pressurized canister containers

This container is mainly used for organic solvents, flammable chemicals, and precursor materials, among others for semiconductor, liquid crystal, medical, and LiB-related applications.

The method of pressurization enables chemicals to maintain their cleanliness while being supplied to production lines.

Stainless steel is used, and the inner surface is electropolished (EP) and cleaned with ultrapure water to achieve a high-quality product.

| Volume | 40L | 100L | 200L |

| Height | 715mm | 934mm | 996mm |

| Drum diameter | 315mm | 512mm | 608mm |

| Material | SUS304・SUS316・SUS316L | ||

| Inner surface treatment | Acid pickling/electro-polishing | ||

- The pressurized method allows the liquid to be in a clean condition when taken out.

- Electropolishing and acid cleaning are available in accordance with the quality of the chemicals.

- Enables ultrapure water rinsing or chemical rinsing to be carried out before delivery.

- Can also be used for precursor materials through the use of a valve.

- Different capacities are available based on your request.

- UN-certified products that can be transported by sea are also available.

- Can be repeatedly used and is sustainable as a link container

- Uses

Electrolyte, High-purity solvents (IPA, PGMEA, etc.), Various cleaning agents, Fluorinated solvents, Precursor materials (TEOS, etc.)

FRP composite pressurized canister containers

It is a composite container combining a highly acid corrosion-resistant FRP or antistatic stainless steel exterior with a PE/PFA inner canister. It is widely used for high-purity acid-based cleaning agents (hydrochloric acid, sulfuric acid, hydrofluoric acid, acetic acid, mixed acid, etc.).

While maintaining the cleanliness of the chemicals using the pressurized method, it enables high-purity chemicals highly corrosive to stainless steel and chemicals of strict metal order to be supplied to production lines.

Wetted materials can be proposed based on the chemical quality requirements.

FRP Exterior

| Volume | 15L | 20L |

| Height | 934mm | 1,100mm |

| Drum diameter | 512mm | 611mm |

| Exterior | FRP | |

| inner casing | PE・PFA | |

- The pressurized method allows the liquid to be taken out in a clean condition.

- Wetted materials can be selected and proposed according to the quality of the chemicals.

- Delivery is possible after washing with ultrapure water or chemicals.

- Reusable and sustainable as a link container. The inner container can be replaced.

SUS composite pressurized canister container

This is a composite container that combines a sturdy, corrosion-resistant, and conductive stainless steel exterior with a PE/PFA inner canister. This is a canister used for a wide range of high-purity cleaning agents, high-purity hydrogen peroxide water, developer solutions (TMAH, etc.), and resist stripper solutions.

The method of pressurization enables chemicals designated as hazardous materials and chemicals with strict metal order requirements to maintain their cleanliness while being supplied to production lines.

Wetted materials can be selected and proposed according to the quality of the chemicals.

SUS Exterior

| Volume | 100L | 200L |

| Height | 846mm | 1,062mm |

| Drum diameter | 513mm | 632mm |

| Exterior | SUS | |

| inner casing | PE・PFA | |

- The pressurized method allows the liquid to be taken out in a clean condition.

- Wetted materials can be selected and proposed according to the quality of the chemicals.

- Delivery is possible after washing with ultrapure water or chemicals.

- Addition of gas venting function means it can be used for hydrogen peroxide, etc.

- Reusable and sustainable as a link container. The inner container can be replaced.

1m3 Containers

This pressurized 1000-L container for high-purity chemicals excels in terms of transportation efficiency.

This is a stainless steel container with enhanced transportation efficiency.

Wide range of types for use with a wide variety of chemicals.

- Round type (for pressurization), square type (drop under own weight)

- Material: SUS304, 316, and 316L

- Inner surface treatment: Enables acid cleaning, sanitary, with HDPE inner container, fluorine resin lining, etc.

- A variety of specifications are available, such as room temperature specifications, heat retention specifications, heat-retention heating specifications, specifications for agitators, specifications for attaching liquid level gauges, etc.

- Capacity: 1000 L, 2000 L, or desired capacity size

- Applicable regulations: UN, Fire Defense Act, No. 20 tank, Class 2 pressure vessel, etc.

- Uses

(Liquids) Chemicals, paints, dyes, drugs, deleterious substances, agricultural chemicals, adhesive solutions, alkaline cleaning agents, acid cleaning agents, developing solutions, water treatment agents, surfactants, metal surface treatment agents, hydrochloric acid, nitric acid, thinners, and various other solvents

(Powders) Various powders and granules, including monomers for resists and electrolytes

SUS Single Container

| Volume | 1000L | 2000L | |

| Method | Square type

(drop under own weight) |

Round type

(pressurized type) | |

| Size | W=1,200mm

D=1,200mm H=1,480mm |

W=1,200mm

D=1,200mm H=1,800mm |

W=2,210mm

D=1,550mm H=22,500mm |

| Material | SUS304・SUS316・SUS316L | ||

| Inner surface treatment | Acid pickling/electro-polishing | ||

Composite Containers SUS Exterior

| Volume | 1000L | |

| Exterior | SUS | |

| Inner casing | PE | PFA |

| Size | W=1,120mm

D=1,120mm H=1,885mm |

W=1,212mm

D=1,212mm H=1,650mm |

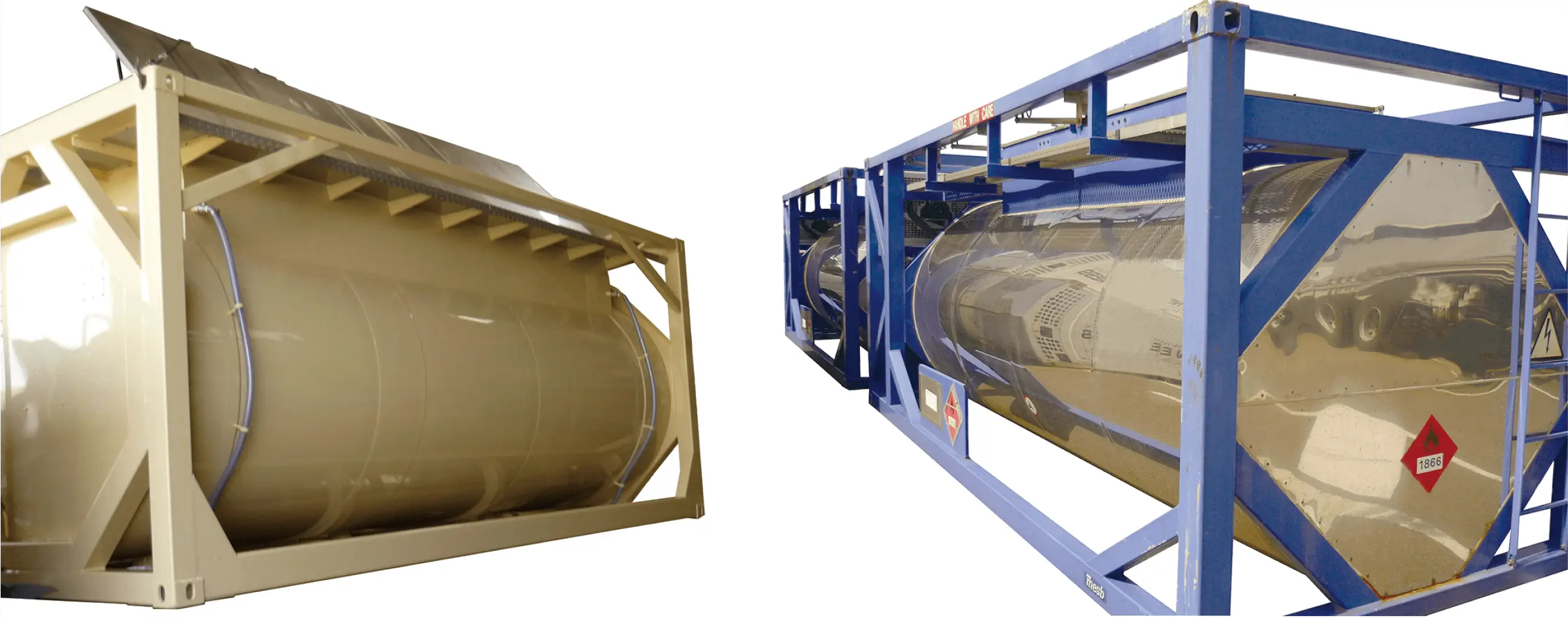

ISO container/trucks

These are medium- and large-sized containers suitable for bulk transportation of semiconductor high-purity chemicals.

Tank trunk for high-purity chemicals

This tank trunk is suitable for transporting high-purity chemicals.

Enables internal surface treatment using electropolishing, fluoroplastic lining, ultrapure water rinsing, etc.

A wide range of support for operation and wetted parts is available.

ISO Tank containers

Large containers are made to customer specifications.

Electropolishing, fluoroplastic lining, ultrapure water rinsing, etc., are performed on the inner surface.

Compatible with standards set forth in the IMDG Code for the Transportation of Dangerous Goods.

We also provide air-driven valve opening/closing and heat-retention/heating.

Composite Containers SUS Exterior

| Material | SUS304・SUS316・SUS316L |

| Inner surface | electro-polishing/fluororesin lining |

| Exterior | Buff polishing/coating |

| Volume | 6,000L~24,000L |