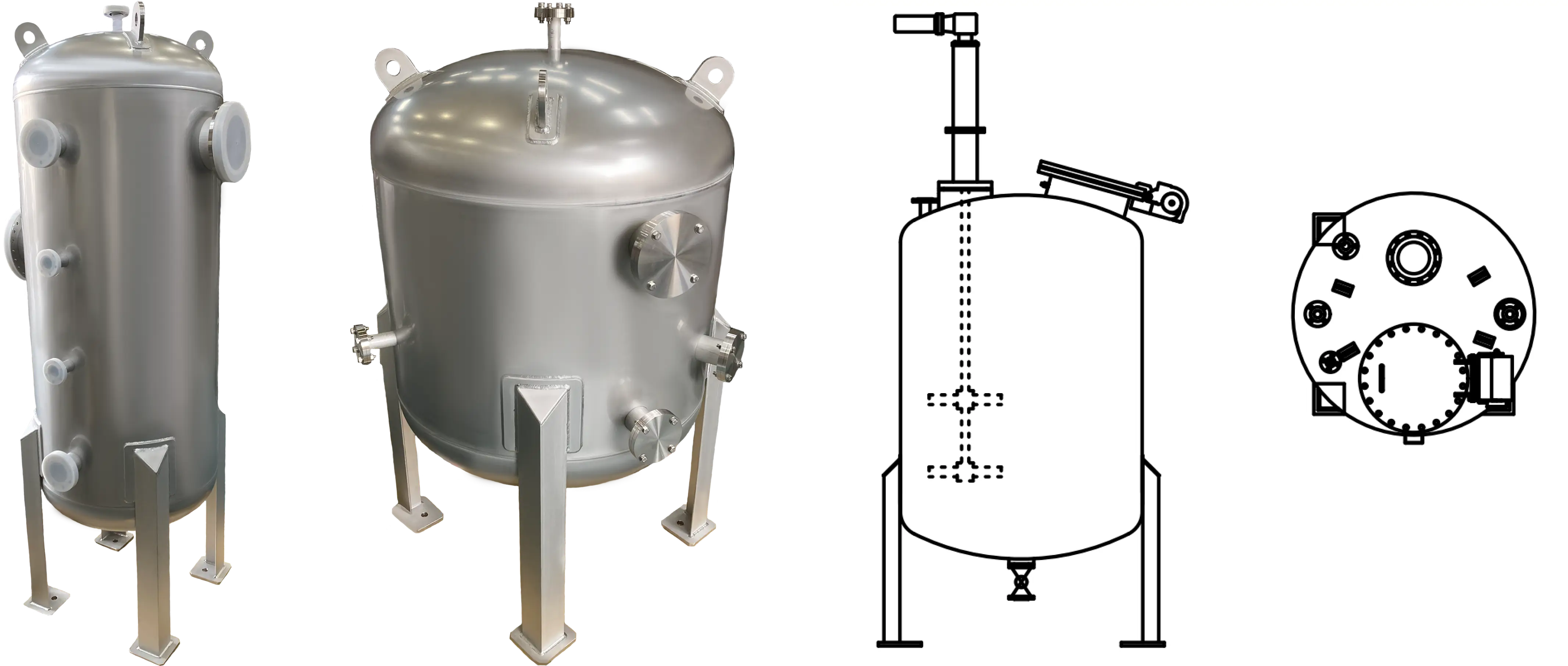

Equipment tanks

We can adjust the specification and size to meet our customer's needs. Our full range of support covers from specification review to filling/mixing maintenance, etc.

Equipment tanks

- Uses: Storage tanks, agitation tanks, reaction tanks, tanks for receiving raw material, etc.

- Capacity: Can be modified to meet your needs.

- Inner surface treatment: Electropolishing, acid cleaning, sanitary, and fluoroplastic lining.

- Regulations: Tank No. 20 of the Fire Service Act, etc. can be accommodated.

- Options: Handling of decompression, chillers, heating, liquid level gauge, viewing window, pressure gauge, safety valve, agitator, etc.

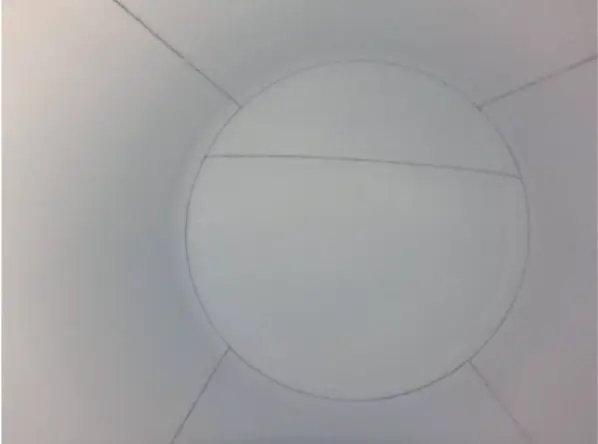

Fluororesin lining

Lining tank new installation, renewal, and maintenance

We supply fluororesin linings with excellent chemical resistance.

Fluororesin linings are linings or coatings that are applied to the inner surface of containers using fluororesins as the material. Due to its excellent properties of fluororesins, they are impervious to acids, alkalis, solvents and other chemicals, and can be used for stable storage of a wide range of products at both low and high temperatures, with a long service life.

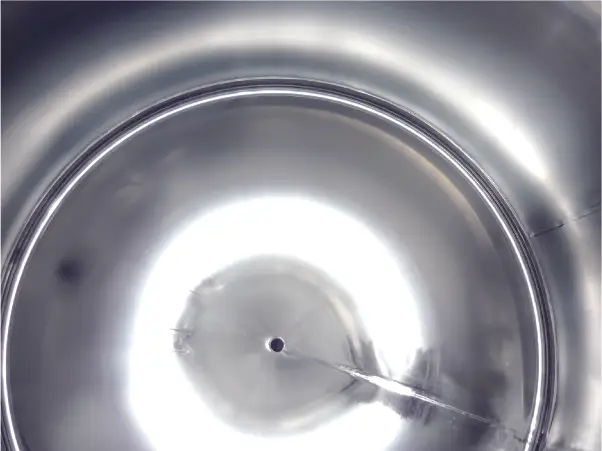

Electrolytic Polishing

New installation, rework, and parts support for electropolishing tank

Electropolishing is used to enhance the corrosion resistance and cleanliness of metal surfaces.

It is a treatment method in which stainless steel products are electrochemically dissolved and the surface is smoothed and mirrored by immersing it in an electropolishing solution. Moreover, by polishing the microscopic irregularities on the surface of the stainless-steel product, the uneven layers affected by machining, etc. are removed and a passive state film is formed to improve the corrosion resistance of the product. It is also the most effective treatment method for deburring and polishing products with complex forms.